![]()

Planetary Yaw Pitch Engine Wind Energy Power Generator Hydraulic Wind Turbine Gear Motor Slew Bearing Slewing Drive Gearbox for Sun Solar Tracker

Introduction

The gearbox in a wind turbine is exposed to a range of harsh and variable conditions. Its components, such as bearings, must be able to withstand these conditions. The successful development and operation of a wind turbine gearbox involves design, modeling, and testing, as well as condition monitoring and maintenance operations, engineering, and lubrication consulting.

Our company offers a wide range of planetary yaw pitch engine wind energy power generator hydraulic wind turbine gear motor slew bearing slewing drive gearbox for sun solar tracker. These products have an output torque range of 1000-80000 N.m and gear ratios of i=300-2000. They are suitable for applications where a slew support (with flange mounted), and electric brake (DC and AC type) is required. The output shaft is splined or with integral pinion, supported by heavy-duty capacity bearings, and applicable motors are IEC electric motors.

Product Description

Our planetary yaw pitch engine wind energy power generator hydraulic wind turbine gear motor slew bearing slewing drive gearbox for sun solar tracker is designed with advanced technology and service solutions, contributing to the transformation of the global energy system. Our reliable, stable, and efficient products and systems save valuable resources, making renewable energy a low-cost and reliable power supply that meets the changing needs of the power generation industry.

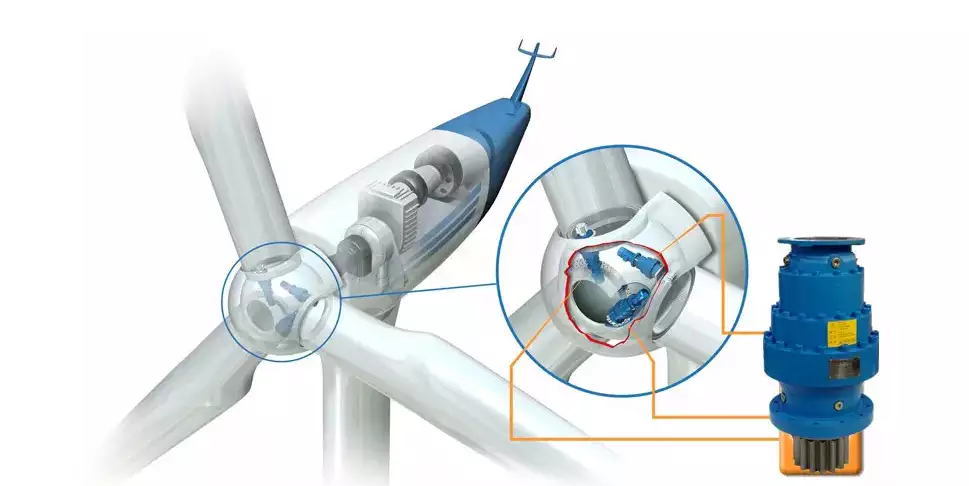

The gearbox is an essential component of the wind power system; it adjusts speed and improves efficiency. Our gearbox is designed to withstand harsh conditions such as loads, stresses, vibrations, and changing temperatures. Our products are equipped with multi-stage planetary structures, suitable to be used in the yaw pitch gearbox, which is one of the most commonly used wind power scenarios.

Related Products

Our company mainly supplies various industrial products, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc. We provide high-quality products at preferential prices and offer thoughtful services. Customers are welcome to customize with drawings and samples.

Frequently Asked Questions

- What is the output torque range of the planetary yaw pitch engine wind energy power generator hydraulic wind turbine gear motor slew bearing slewing drive gearbox for sun solar tracker?

- What gear ratios are available for this product?

- What type of support is provided with this product?

- What type of electric brake is available for this product?

- What motors are suitable to be used with this product?

Introduction to Performance Characteristics of Pitch Drive

Pitch drive is a key component of pitch control systems in wind turbines. It is used to adjust the angle of the blades and regulate the speed of the turbine. The performance characteristics of pitch drive can be summarized as follows:

- Precision: Pitch drives are designed to operate with high precision, allowing for accurate blade angle adjustments.

- Reliability: Pitch drives are critical components of wind turbines, and must be highly reliable to ensure consistent operation.

- Efficiency: Pitch drives are designed to operate with high efficiency, minimizing energy losses and maximizing power output.

- Load Capacity: Pitch drives must be capable of handling high loads, as they are responsible for adjusting the angle of the blades in response to changing wind conditions.

- Durability: Pitch drives must be durable enough to withstand the harsh operating conditions in wind turbines, including extreme temperatures, wind speeds, and loads.

Types and Characteristics of Pitch Drive

There are several types of pitch drive, including hydraulic, electric, and manual. Hydraulic pitch drives are the most common, and are often used in large wind turbines. Electric pitch drives are typically used in smaller turbines, while manual pitch drives are used in emergency situations. The characteristics of pitch drive can vary depending on the type and material used. For example, pitch drives made of aluminum are lightweight and easy to install, while those made of steel are more durable and better suited for harsh environments.

Application of Pitch Drive in Various Fields

Pitch drive is not only used in wind turbines, but also in aerospace, automotive, machine tools, robotics, and other fields. In aerospace, pitch drives are used to adjust the angle of aircraft wings and control their flight. In the automotive industry, pitch drives are used in the suspension system to adjust the angle of the wheels and improve stability. In machine tools, pitch drives are used to adjust the angle of cutting tools and improve accuracy. In robotics, pitch drives are used to adjust the angle of robotic arms and improve precision.

Future Development Trends and Opportunities of Pitch Drive Products

As demand for renewable energy continues to grow, the market for pitch drive products is expected to increase. In addition, advancements in technology are leading to the development of more efficient and reliable pitch drives. Some of the key trends and opportunities in the pitch drive market include increased use of lightweight materials, improved control systems, and the development of pitch drives for use in offshore wind turbines.

How to Choose a Suitable Pitch Drive

Choosing a suitable pitch drive depends on several factors, including torque and load requirements, speed and precision, environmental conditions, space constraints, efficiency, and power consumption. Torque and load requirements are the most important factors, as they determine the size and power of the pitch drive needed. Speed and precision are also important, as they affect the accuracy of blade angle adjustments. Environmental conditions, such as temperature and humidity, must also be considered, as they can affect the performance and durability of the pitch drive.

Summary

Pitch drive is a key component of pitch control systems in wind turbines, as well as in aerospace, automotive, machine tools, robotics, and other fields. It is designed to operate with high precision, reliability, efficiency, load capacity, and durability. Pitch drives are available in several types and materials, and choosing the right one depends on several factors, including torque and load requirements, speed and precision, environmental conditions, space constraints, efficiency, and power consumption.

Author: Dream

Disclaimer: All the content of this page is from the internet, and is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content, and our replacement parts are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.